Surfaces

Surfaces

1. Introduction

Until a few years ago, there was scarcely any discussion about the surface finish of printed circuit boards. Solder applications used hot air levelling finishes, bonding or connector applications used Ni/Au (electroless or electroplated).

Apart from the RoHS regulations, effective since 01.07.2006, it is increasingly the changing technical requirements on printed circuit boards which are driving the discussion about alternative finishes. Even if an increasing fraction of connections use alternative technologies, the main technology for connections in module manufacture remains soldering.

CONTAG has addressed this challenge and can basically offer all of these finishing variants. The question is not which alternatives we can offer, but which alternative you need! We would like this technology information sheet to be seen as something to help our customers make decisions.

2. Requirements on a universal finish

The increasing functional density of electrical modules requires the grid dimensions for printed circuit boards to be reduced more & more. In addition, changing technical requirements and new component assembly processes as well as the combination of differing techniques (e.g. COB and SMT) are placing high requirements on the performance of contact surfaces on printed circuit boards.

In parallel to this the requirements on the basic material are increasing, which must have improved temperature-dependent characteristics and dimensional stability for multiple soldering processes with a higher temperature profile.

The characteristics of a universal printed circuit board finish:

- Support fine structures

- The pad planarity

- Solderable, even several times and selectively at higher temperatures

- Bondable

- Suitable for press-fit technology

- Environmentally compatible

- Cost effective

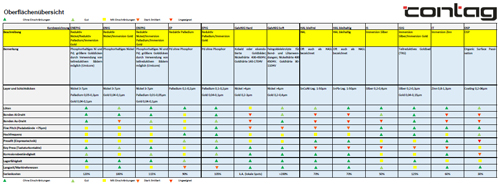

3. Overview surfaces

Overview as PDF

Overview as PDF

For more detailed technological questions on printed circuit boards, please contact our CONTAG-team (+49 30 351 788 - 300 or team@contag.de).

Your personal contact

+49 30 351 788-333

team contag.de

contag.de